Turbine bypass valves - TBPVs

In thermal power stations, the whole process of generating energy revolves around the turbine. At the turbine, the kinetic energy of the gas/steam is converted into rotational energy and then, in the generator, in electrical power.Effectively protecting these complex components from mechanical damage is a key concern of power station operators and for this reason a bypass valve BPV is installed at every turbine stage (HP, IP & LP).

In doing so, TBPVs must perform both pressure reduction as well as temperature control.

Pressure reduction is accomplished with the trim within the valve body. The inlet pressure is controlled by an upstream pressure controller, signalling the valve to modulate and maintain the pressure at the required set point. Alternatively it can be sent a digital signal to the valve to quick open or close the control system as required.

Temperature control is accomplished through the addition of water (coolant) to the steam, reducing the specific enthalpy of the steam (a process called desuperheating). A separate water control valve supplies the correct amount of water to the desuperheating mechanism (typically spray nozzles) within the steam conditioning valve. A downstream temperature transmitter typically operated in conjunction with a feed-forward algorithm within DCS will dictate the amount of water to be injected into the steam by the water control valve or WCV.

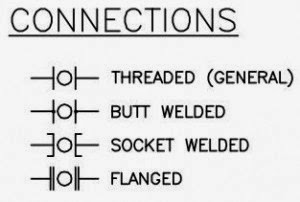

Valve inlet and outlet connections (commonly buttweld or flanged for that specific application) should be provided to suit customers piping and pressure requirements, and to maintain inlet and outlet steam velocities to reasonable levels (<80m/s –250ft/s).